Japanese 5 stars 20 January 2017

Charm of Shogi Equipment Changing through Long Usage –Interview about Producing Shogi Pieces with Kikusui-san, Artisan of Shogi Pieces

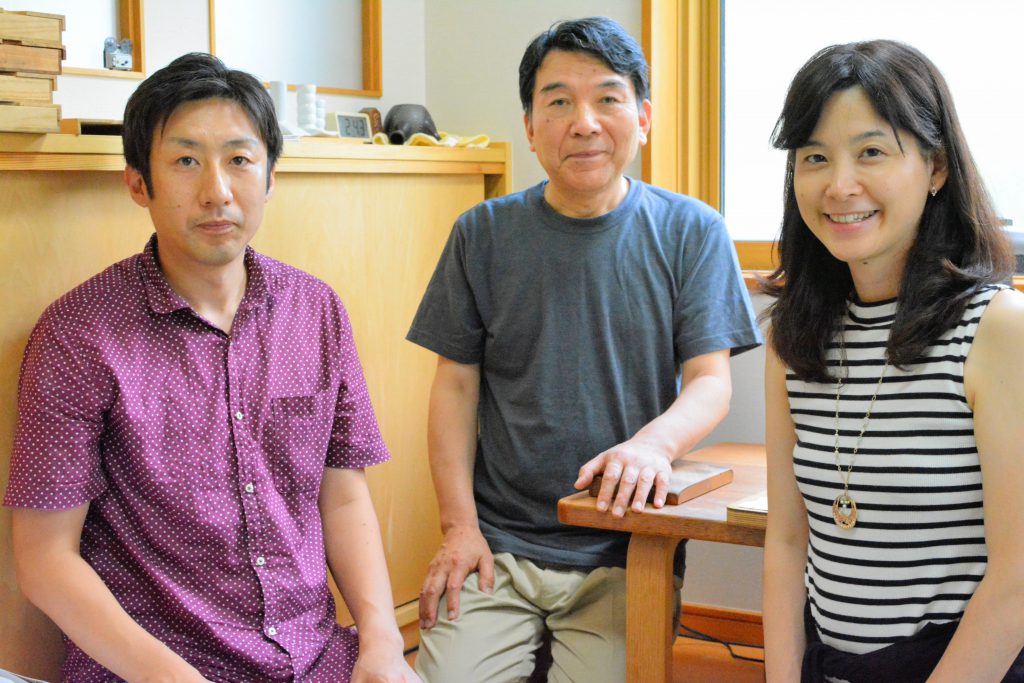

On 9 August, 2016, I interviewed with Mr. Kazuo Sakurai (hereafter Kikusui-san) who made our exquisite Shogi pieces used in the third Kyoku of the 74th-term Meijin Title Match (“Kyoku” is suffix to count Shogi games.) In this interview, I asked him about producing Shogi pieces.

The interview was taken place in Tendo City, Yamagata prefecture known for production area of Shogi pieces.

In this interview, a son of Kikusui-san, Mr. Ryou Sakurai (hereafter Tousui-san, since he is known as “Tousui-san”) was with us. He is also active as a craftsman of Shogi pieces.

The Process of Producing Shogi Pieces

Akiko Nakakura (hereafter Akiko): Could you tell me the process of producing Shogi pieces?

Kikusui-san: We purchase rectangular shape woods that are sawn from one lumber and then we dry them at least 4 to 5 years. After drying, we cut them to convert from rectangular to pentagon respectively. There are three types of woods size; one for big pieces such as Oushou, or King, another for Kin (Gold) and Gin (Silver), the other for small pieces such as Fu, or Pawn, and Kyousya, or Lance. During the process of making Oushou, if any wood piece is stained or annual rings of the piece doesn’t emerge beautifully, that piece will be used for making Kin/Gin. Basically, in a Shogi game two players needs 40 pieces in total; 20 for each player. In order to produce one pair of Shogi pieces, we need about 50 wood pieces and we tentatively choose and make a pair from them for each piece.

Akiko: You mean you don’t use all wood pieces you have, do you?

Kikusui-san: The most difficult part of the process of making Shogi pieces is to prepare as many wood pieces with unity of wood grain as number of needed pieces. According to the purpose, the required level may change. When we make equipment for a game by professional players, we are required to have quite high quality of woods. Therefore, even if we have 50 pieces, sometimes it is difficult to find perfect pairs that we are completely satisfied with. In that case, we keep working on preparing pairs over and over again. Surely, inexpensive pieces are gone through such process and they are often without regard to the unity of wood grain

Akiko: I see. I thought that in order to produce Shogi pieces, simply craftsmen cut one lumper into small pieces and that alone could make same wood grain pattern appear on each slice. I was wrong. You need to select wood for every single piece carefully.

Kikusui-san: Shogi pieces that you see are finished products and already paired. You hardly ever picture their previous shape.

Akiko: Do you usually work on the entire process, from choosing the woods to finish them, by yourself?

Kikusui-san: We do choose wood pieces and paint characters to be swelled on pieces by a special brush by ourselves. In Tendo City, there are no other craftsmen do the same as we do. Recently, throughout the nation, there are some amateurs enjoying to make Shogi pieces as a hobby.

The Value of Equipment Born after Long Usage

Akiko: Could you tell me about these pieces?

Kikusui-san: I made these pieces with my colleagues, hoping to produce high quality Shogi pieces in Tendo. Of course, Shogi pieces are equipment used in a Shogi game. I heard the quality of pieces was determined after long usage, like 10 years or even 20 years. We, Japanese, used to have a culture to enjoy the change across the ages. In Japan, amber colour is called “candy colour.” This colour of plain wood will gradually change the colour in amber over time. Encountering the amber colured pieces, I become keenly aware of the owner’s cherishing the pieces.

Akiko: Yes, indeed. The colour of piece changes and will have depth to the colour with polishing for years.

Kikusui-san: By the way, what do you think would be the best to polish pieces?

Akiko: I guess…Is it be camellia oil?

Kikusui-san: The answer is polishing with a dry cloth only, no oil. Washed-out cotton underwear, on particular! In Japan, we have traditionally often used Ibotarou-mushi, a kind of scale insect, for polishing plain wooden products to be glossy. That scale insect can be found on maple trees, which is like small shell and inside shell it has something like cotton containing nutrient.

Akiko: Really? I didn’t know that.

Kikusui-san: Back to what I was saying, it seems there are many people who don’t know how to care Shogi equipment including polishing pieces. For example, boxwood used for Shogi pieces is very hard, and Shogi pieces have horny shape. If you handle them roughly, each point will be cracked easily. Also, long nails will give damage on their faces. I heard you would provide opportunities for children to use Shogi equipment used in Meijin title match. Children who don’t play Shogi regularly tend not to know how to use. Unsurprisingly, professional players are familiar with Shogi equipment and handle them with special care. They drop a piece on a board from piece box carefully and make sure if they don’t miss any piece before they stow them into box. In that sense, if children could learn how to use equipment properly from professional Shogi players, it would be a great educational opportunity, not just a good chance to use professional Shogi equipment.

Akiko: In our, I-tsu- tsu’s, events, I always wear Kimono and show children all my actions and manners, which start from the very beginning of setting up pieces, say picking up them from the box. Surprisingly, immediately after I sit down on tatami mat, children spontaneously become quiet and observe every single my action seriously. What happen after that is no one handles equipment roughly.

Kikusui-san: The younger generation right now is mainly raised up, using manufactured products. Basically, they hardly ever use lacquer or iron ware, nor wear kimono except in special occasion. As a result, they aren’t aware of appreciation for uniqueness of handcrafts and the change caused by careful long usage. Instead, they prefer uniformity of goods. I hope the younger generation would view traditional Japanese crafts as something new, but difficult.

Shogi Pieces as One of Traditional Japanese Culture

Akiko: I have heard that you teach about Shogi pieces at some elementary schools.

Kikusui-san: I teach about them as one of school subjects related to traditional industries. I am a craftsman, so I don’t teach how to play Shogi, but teach Shogi in terms of handy crafts. In a class, I let children make a key chain from boxwood with a hole and draw characters, “Ohshou” or King, with a felt pen. I expect children will become familiar with Shogi pieces, touching woods and making something from woods.

Akiko: I have seen several kinds of Shogi pieces, so far. After all, I think I like boxwood, as it gives me more warmth.

Kikusui-san: Tendo City is a place of traditional industry for Shogi pieces. Nevertheless, high quality pieces used in a professional game were not made. In Tendo, mass production was the first priority up to about 40 years ago. Then those days, some craftsmen including me decided to produce exquisite ones to be used in title match, in here Tendo city. It was Oushou Tournament of 1980 that pieces produced in Tendo were used for the first time.

Akiko: Our Meijin Title Match pieces that you made are elaborated in details and really exquisite.

Kikusui-san: One year ago, I got an order from Shogi Association to produce pieces and presented them to Princess Akiko of Mikasa who is an honorary president of national invitational championship Shogi tournament of middle school students. She has real appreciation for traditional Japanese culture and enjoy playing Shogi. I attended the presenting ceremony as an expositor with a Lord Mayor. Shogi piece craftsman is a kind of “Kuroko”, a stage assistant, and the duty for us is to produce Shogi pieces for players. It was terribly revered but honored to present my products to Princess Akiko.

No Exception, Succession Issue among Shogi Piece Producer

Akiko: You are making efforts to produce heirs, right?

Kikusui-san: I provide lectures to train the cutting technique in order to establish Tendo Shogi pieces as a local industry. Now, there are nine people attending my lectures, including five females. Their age range from the late 20’s to 40’s. I told them that they needed to be prepared for becoming professionals, if you would want to learn with me. They have been working on very hard.

Akiko: Females are more! Do they like Shogi?

Kikusui-san: Tow of those females are successors of specialized store, and the others don’t have experiences to play Shogi. Some of the ladies even don’t know what materials are used for pieces. Those Shogi beginners are taking my lectures rather to get engaged in making traditional products, not to specialize in Shogi equipment. It isn’t a big deal what made them have interest in this job. The problem is that the younger generation can’t make enough time to learn how to produce pieces. People in age of late 20’s and 30’s tend to be very busy with small children.

Akiko: Until you started providing lectures, did you take apprentices to pass on technique?

Kikusui-san: I started this job in 1973 and that was the last days when people have the system of half year apprentice. Recently, due to the development of the internet, people can easily get to know the way to make pieces and there is scarcely a person who wants to be or take an apprentice, I suppose.

Akiko: If you don’t take apprentices, is family business common, like you and Tousui-san?

Tousui-san: I didn’t want to make Shogi pieces as my profession. I think it is the case for the other craftsmen as well. In my case, I didn’t have opportunities to see work place and what was going on there. Presumably, my parents didn’t want me to take over my father’s work.

Kikusui-san: In Tendo city, most craftsmen have a side job and some who go into a profession are struggling to make a living. So, you know, few have a desire to make their own children successors.

Tousui-san: There are so much to learn and time is needed to master them. It took me long time to produce “Moriage-Koma” constantly.

Kikusui-san: In past days, we had to work as a subcontractor for many years without revealing own name as a producer. It took a quite long time to gain public reputation as a Shogi piece craftsman. But now, the internet can bring out your name in the world, regardless of social reputation.

As Shogi Piece Maker, the Name of “Kikusui”

Akiko: Your name, Kikusui, is beautiful name, isn’t it?

Kikusui-san: My real family name is Sakurai. The teacher from who I learned producing Shogi pieces told me about the place named “Sakuriai”, the same as mine, and the place had some connection with Masashige Kusunoki, who was a warrior in the late Kamakura era. His sign was “chrysanthemum and water”. These two words are pronounced together Kikusui (菊水) in Japanese. My teacher named me after this. As chrysanthemum is flower for the royal family in Japan, I thought it was too much for me. I asked advice another teacher of Japanese tea ceremony and he advised me to put a different Chinese character, 掬 for “Kiku” instead of 菊 (In Japanese, the name of Kikusui-san is written as 掬水. The character of 掬 means scooping and 水 for water in English.)

Akiko: Tousui-san (淘水), your name also contains the character meaning water, 水.

Tousui-san: I make Shogi pieces with my name, Tousui. I selected the character representing water, because I hoped to scoop something wonderful. I really like my name.

Kikusui-san: We produce Shogi pieces from engraving wooden pieces but do not create them. Now people often use duplications. However, I feel something odd to put my name on the copy. As long as I use my name Kikusui, I don’t use the materials as they are. I create the shape of characters drawn on a piece and keep making ingenious attempt to draw character in my own way. Incidentally, too much cursive style is difficult to read, therefore I keep in mind using popular style. When it comes to the matter of elaborateness or intricacy of works, I am too old and might lose my edge. But at the same time, I would like to claim that my experiences could make me see more that I used to.

Postscript–After the Interview–

Kikusui-san whose real name is Mr. Kazuo Sakurai speaks in an arresting moderate tone. Starting from wooden materials, two hours passed before I knew it.

His son Tousui-san, Mr. Ryou Sakurai, was with us throughout the interview. Kikusui-san sometimes asked Tousui-san, “Go and get ‘That’.” Without saying all, Tousui-san understood Kikusui-san’s intention and answered his request; they get along fine. I saw the relationship between a teacher and an apprentice in their communication.

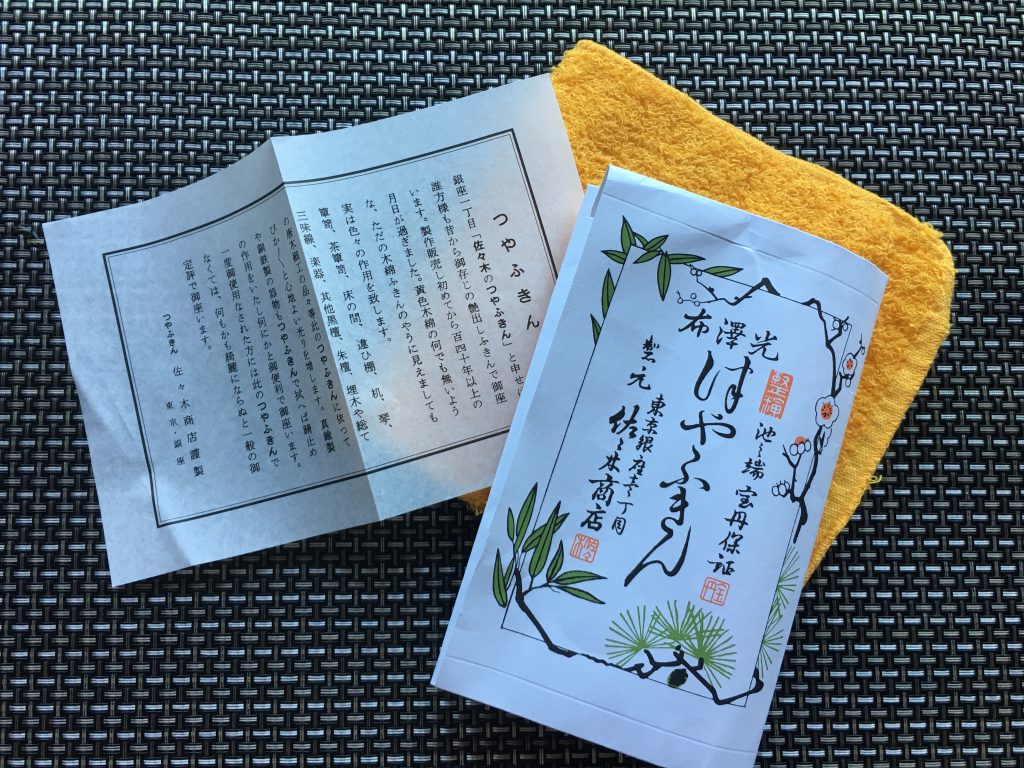

During this interview, Kikusui-san showed me several things such as woods, cloths, pictures, and so on. Among them, the most impressive one was a cotton cloth to polish pieces from Sasaki Shoten in Ginza, Tokyo (Please refer to the picture below. The name of this cloth is “Tsuyafukin”, and it has been sold over 140 years.) Kikusui-san gave me it as a present and said, “I have continued to be particular about this because I can give wonderful shin on pieces with this cloth.” I think this is also their prides as craftsmen to make Shogi equipment, Shogi pieces.

These days, since you can sell Shogi pieces via the Internet, more people enjoy making pieces as a hobby than before. To the contrary, Kikusui-san has kept his professional working style.

“Even though there is the specific style of characters to be drawn on pieces, I would like to add my sense as a professional Shogi piece maker as much as possible. It could be the highlight of my career. I will seek for the way to deepen my work”, said Kikusui-san impressively.

The character of Ohshou, or King, drawn by Kikusui-san in Kinki style, which is one of writing styles of kanji on Shogi pieces, is a bit smaller than that of the others’. I feel its decency and modesty created by Kikusui-san’s ingenious efforts.

Just before the end of this interview, Kikusui-san said that he had something to show me. He gently and slowly took out pieces, which his daughter produced. He asked me, “I would like to make sure if these pieces could be put out in the world. I am afraid that they are still not good enough.” “No, not at all”, I was humbled and replied.

Those pieces gave feminine and delicate mood.

After many years of training, she was admitted to be a professional who can produce commercial goods. I do hope that she will continue to be active.

In our Blog, we have introduced some craftsmen who engage in traditional Japanese culture.

If you haven’t visited us yet, now is your chance!